Osteoprogenitor cells are the stem cells that exist in bone and generate osteoblasts. They are derived from ancient mesenchymal cells. Accordingly, establishing a new biocompatible material is mandatory that at as a substrate for growth, proliferation as well as differentiation of osteoprogenitor cells. In this regarded, Poly (e-caprolactone) (PCL) is a good option. It is an FDA-approved biodegradable polymer that is employed as resorbable sutures. It has also been investigated as scaffold for skin1, heart muscle2 as well as bone3 tissue engineering.

Scientists have reported the manufacture and biocompatibility of linear polycaprolactone fumarate (PCLF). Moreover, it can also be utilized in nerve tube regeneration that is astonishing. In addition, this substance also has the potential to be employed as injectable material for treatment of skeletal defect when the material in semi-crystalline form is brought near to melting temperature4.

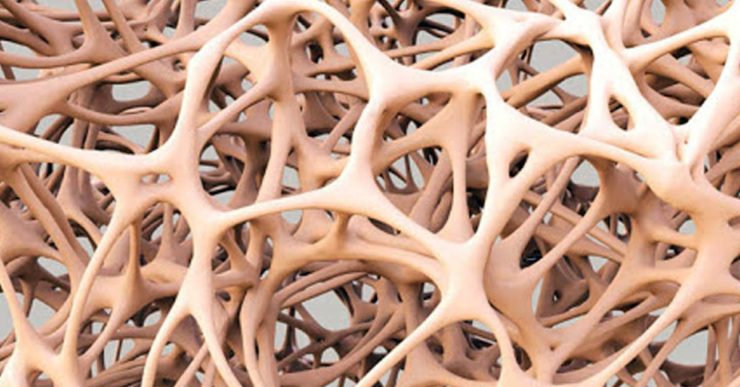

This situation motivated scientists for conducting a new research in order to assess the effectiveness of poly(caprolactone-trifumarate) (PCLTF) as scaffold for in vitro Bone Marrow Stromal (BMS)-derived osteoblasts growth, proliferation as well as differentiation by using scanning electron microscopy5.

For this purpose, researchers synthesized the PCLTF into viscous liquid form, with surplus of unreacted hydroxyl groups (-OH) that exist within the PCL-backbone. Accordingly, it is thought that hydroxyl groups can improve hydrophilicity of the newly manufactured polymeric macromere, which then can assist cells attachment onto the scaffold5.

In this experiment, Scanning Electron Microscopy (SEM) showed osteoblasts adhesion and proliferation on PCLTF scaffold after three days culture. However, at 14th day, scientists found fibrillar collagen network and calcified globuli as they were deposited on PCLTF scaffold and at 28 days huge mineralization on PCLTF was observed as well. ALP secretion was noticed in both cells seeded PCLTF scaffold and positive controls and their total ALP fold production were not different, considerably.

Moreover, Von-Kossa staining determined calcium mineral pigments present on cells seeded PCLTF scaffold. Bone-like tissue structures were found on H & E stained slides of cells seeded PCLTF scaffold after twenty days of incubation. BMS-derived osteoblasts growth, proliferation and differentiation were observed on synthesized PCLTF porous scaffold. Conclusively, scientists stated that PCLTF can be efficiently employed as scaffold for bone tissue engineering.

Key words: osteoprogenitor cells growth, resorbable sutures, polycaprolactone fumarate, osteoblasts growth, fibrillar collagen, mineralization, hydrophilicity

References:

- Dai, N.T., M.R. Williamson, N. Khammo, E.F. Adams and A.G.A. Coombes, 2004. Composite cell support membranes based on collagen and polycaprolactone for tissue engineering of skin. Biomaterials, 25: 4263-4271.

- Shin, M., O. Ishii, T. Sueda and J.P. Vacanti, 2004. Contractile cardiac grafts using a novel nanofibrous mesh. Biomaterials, 25: 3717-3723.

- Kweon, H.Y., M.K. Yoo, I.K. Park, T.H. Kim and H.C. Lee et al., 2003. A novel degradable polycaprolactone networks for tissue engineering. Biomaterials, 24: 801-808.

https://www.ncbi.nlm.nih.gov/pubmed/12485798 - Jabbari, E., S.F. Wang, L.C. Lu, J.A. Gruetzmacher and S. Ameenuddin et al., 2005. Synthesis, material properties and biocompatibility of a novel self-crosslinkable poly (Caprolactone fumarate) as an injectable tissue engineering scaffold. Biomacromolecules, 6: 2503-2511.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2530909/ - Yoke Chin Chai, WAB Wan Abas and Kah Hwi Kim , 2006. Osteogenic Expression of Bone Marrow Stromal Cells on PCLTF Scaffold: In vitro Study. Asian Journal of Cell Biology, 1: 40-47.

https://scialert.net/fulltext/?doi=ajcb.2006.40.47 - Isra Ahmad, 2020. Role of Polycaprolactone-trifumarate in Bone Tissue Engineering Asian J. Emerg. Res., 2(2): 84-85.

https://ajer.scione.com/cms/abstract.php?id=136

Add comment